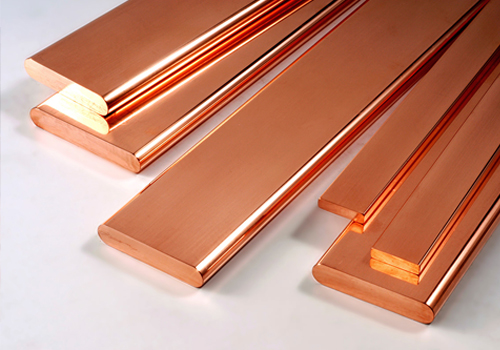

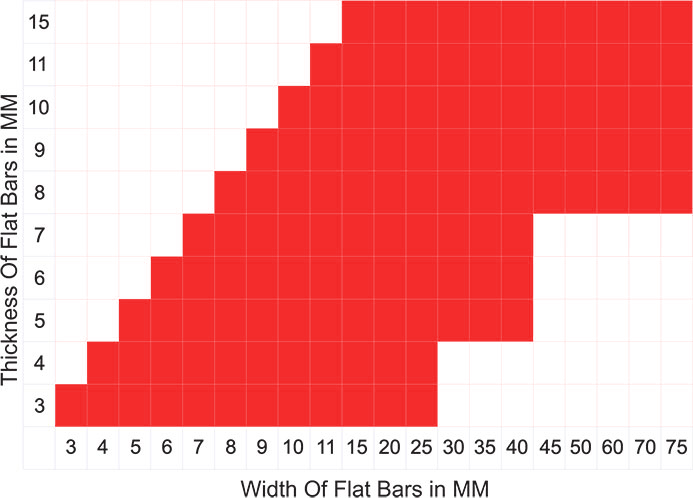

Flat Bar (Max to Min)

_

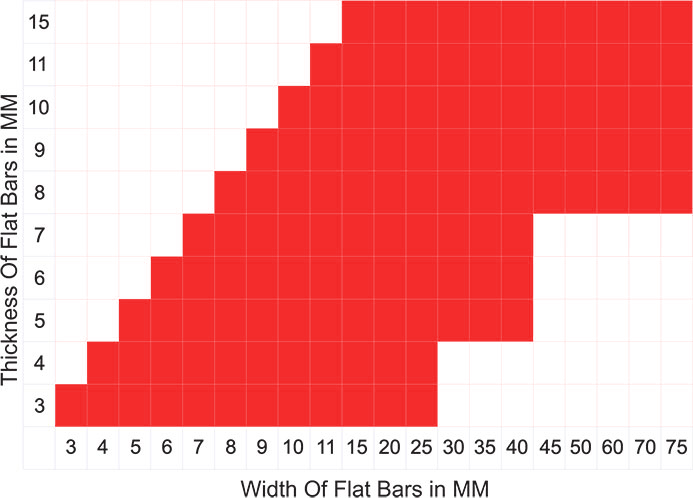

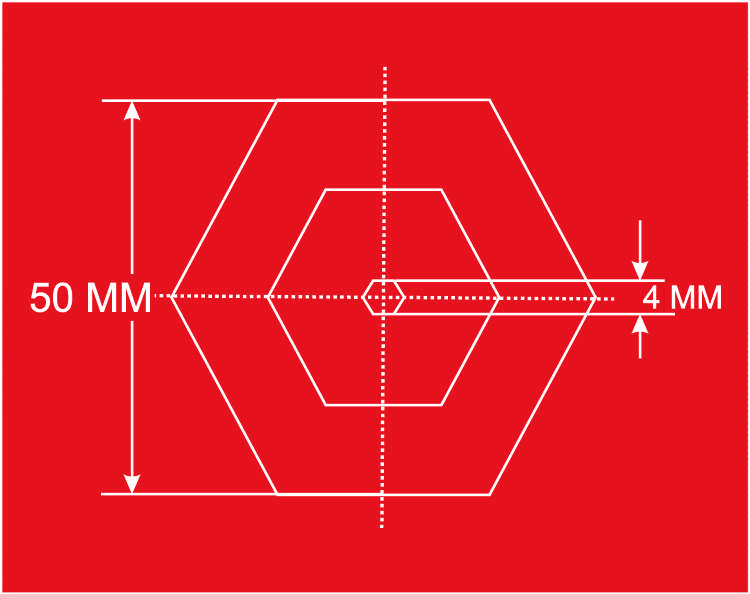

Hexagon Bars (Max to Min)

_

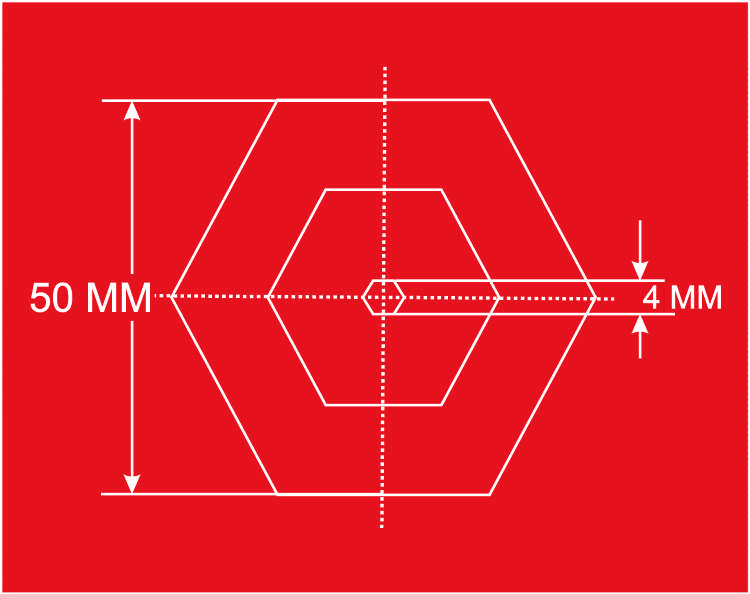

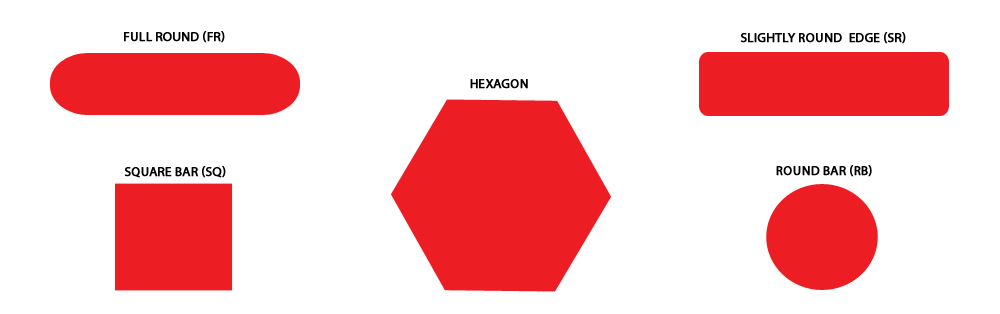

Shape

_

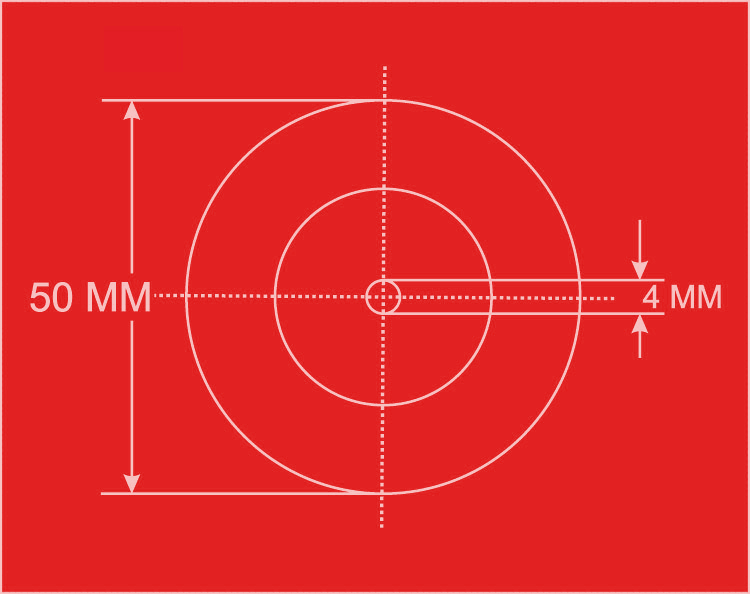

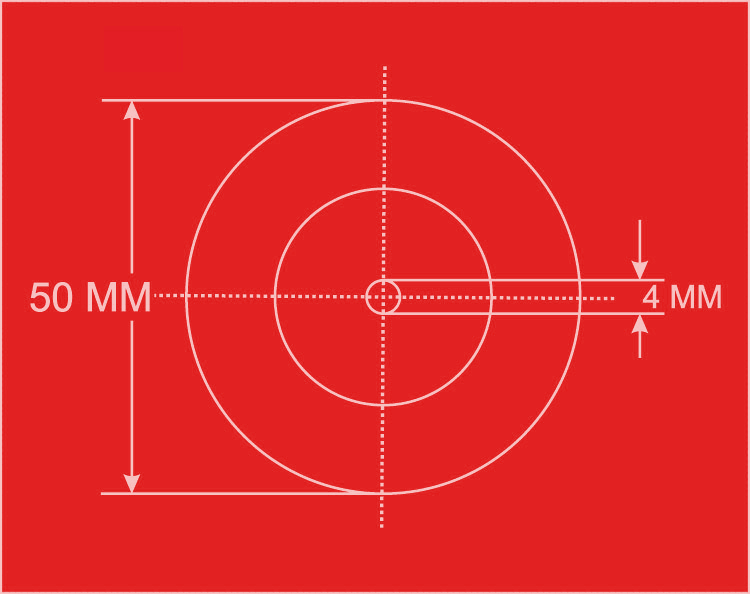

Round Bar (Max to Min)

_

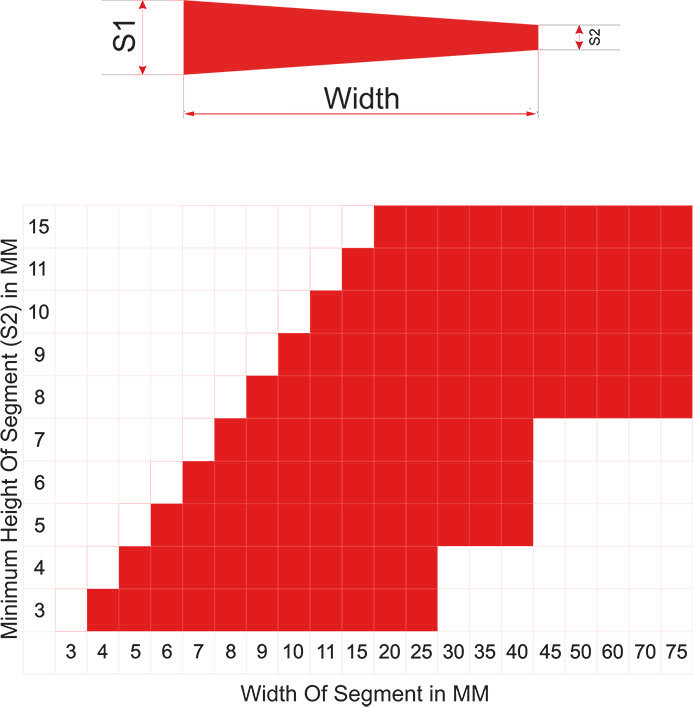

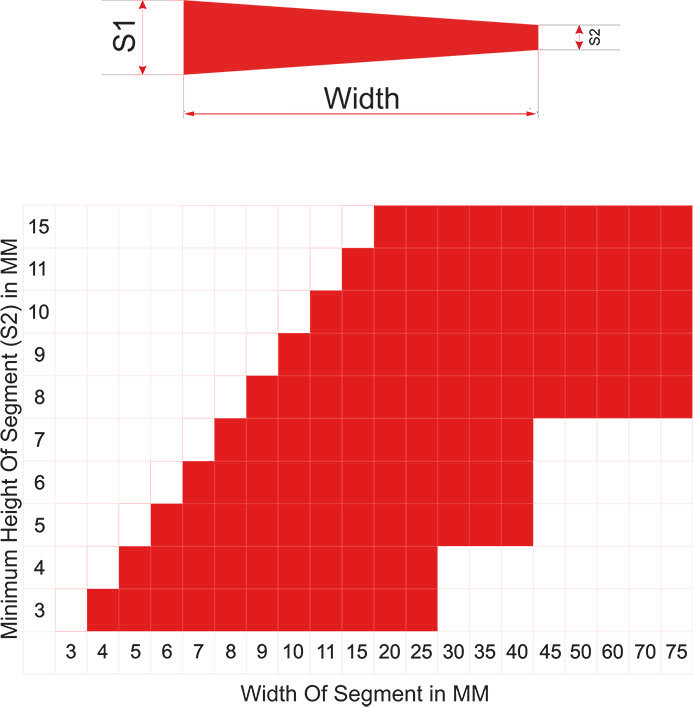

Segments (Max to Min)

_

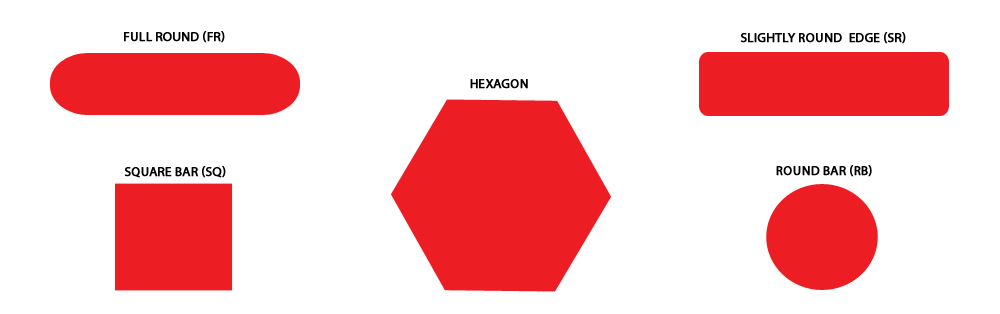

Copper Profiles

COPPER PROFILES FOR ELECTRICAL APPLICATIONS

_

COPPER PROFILES FOR HEAT SINKS OR CPU COOLERS

_

Flat Bar (Max to Min)

Hexagon Bars (Max to Min)

Shape

Round Bar (Max to Min)

Segments (Max to Min)

COPPER PROFILES FOR ELECTRICAL APPLICATIONS

COPPER PROFILES FOR HEAT SINKS OR CPU COOLERS