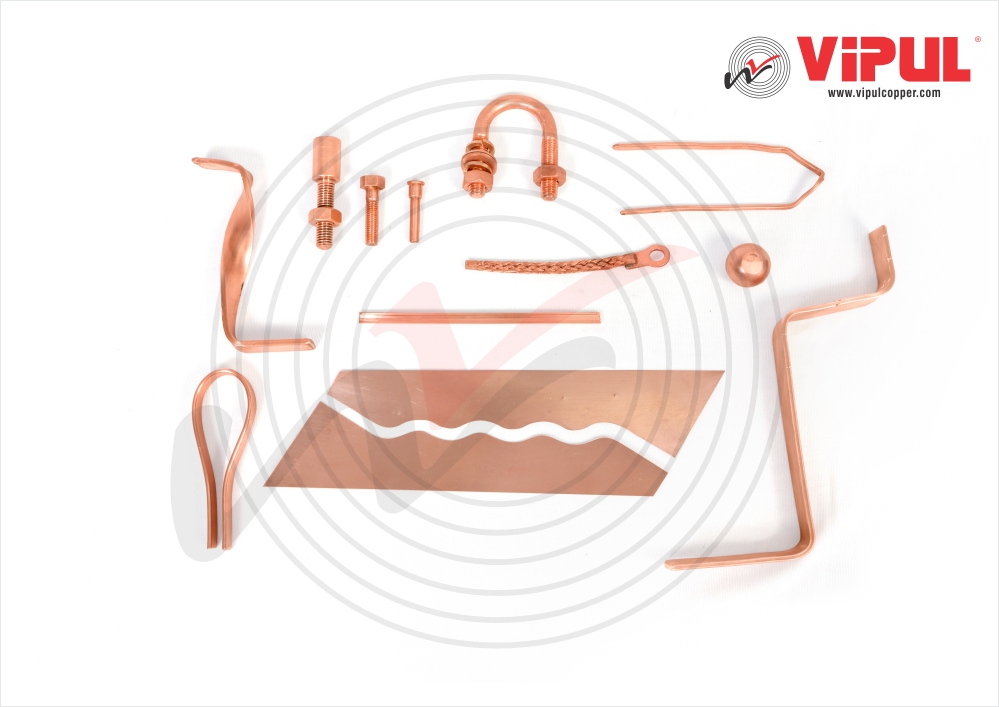

ABOUT US

- Over three decades of copper Industry.

- Trusted by a satisfied global clientele.

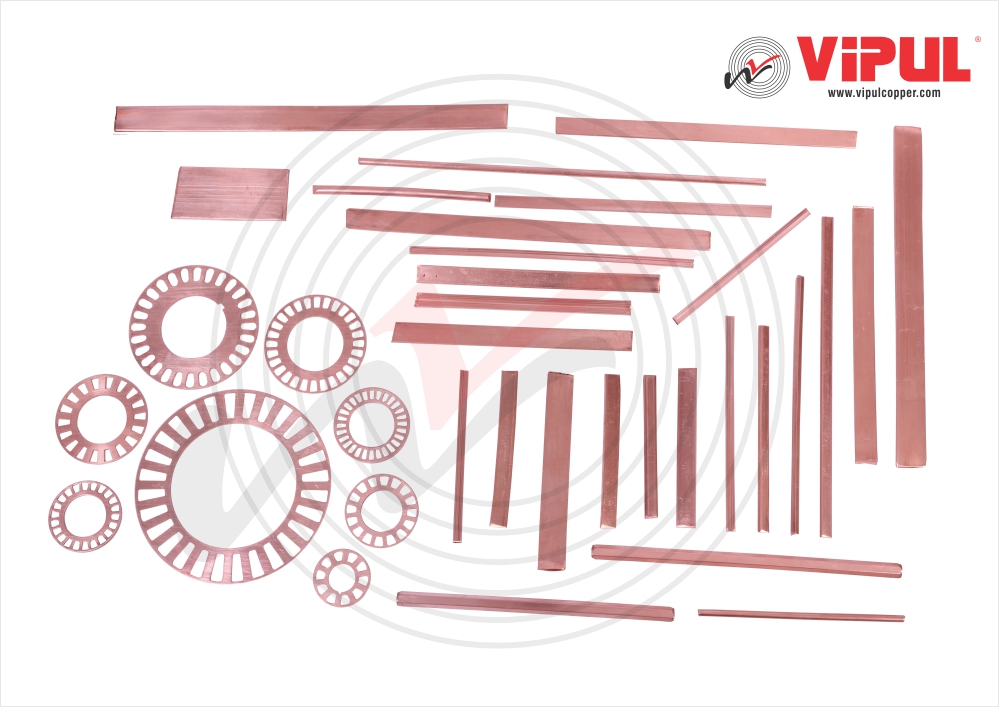

- Electrical Motor Material Solution.

INDUSTRIES WE WORK WITH

We Manufacture products for a wide range of areas.

LV Switchgear

MV Switchgear

HV Switchgear

Industrial Motors

Transmission & Distribution

Railways

Aerospace

Automotive

Marine

Defence

Engineering

Gravure Industries

Get Free Consultancy or

+91 82009 90772

Global Reach, Local Excellence

_

Connecting Continents: Our Presence in 10+ Countries

Experience the seamless global distribution network of vipul copper. With a footprint in over 10 countries, we ensure quality products reach you, wherever you are.

- Strong International Network

- Cultural Adaptability

- Quality Assurance

- Customer-Centric Approach

- Adaptive Supply Chain

- Sustainable Practices